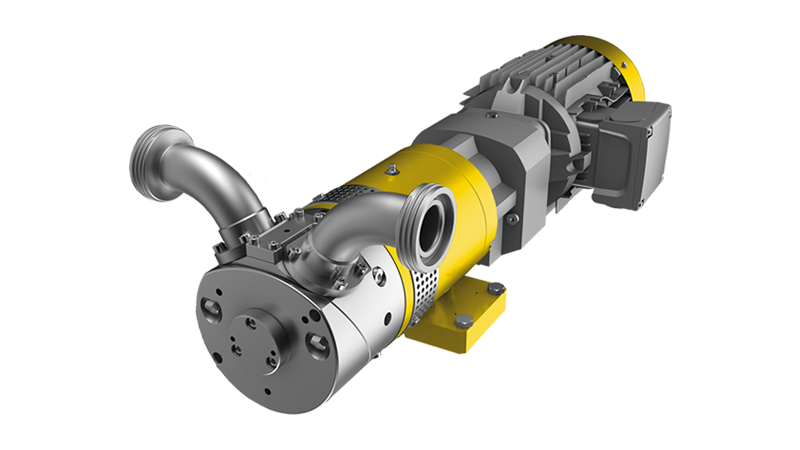

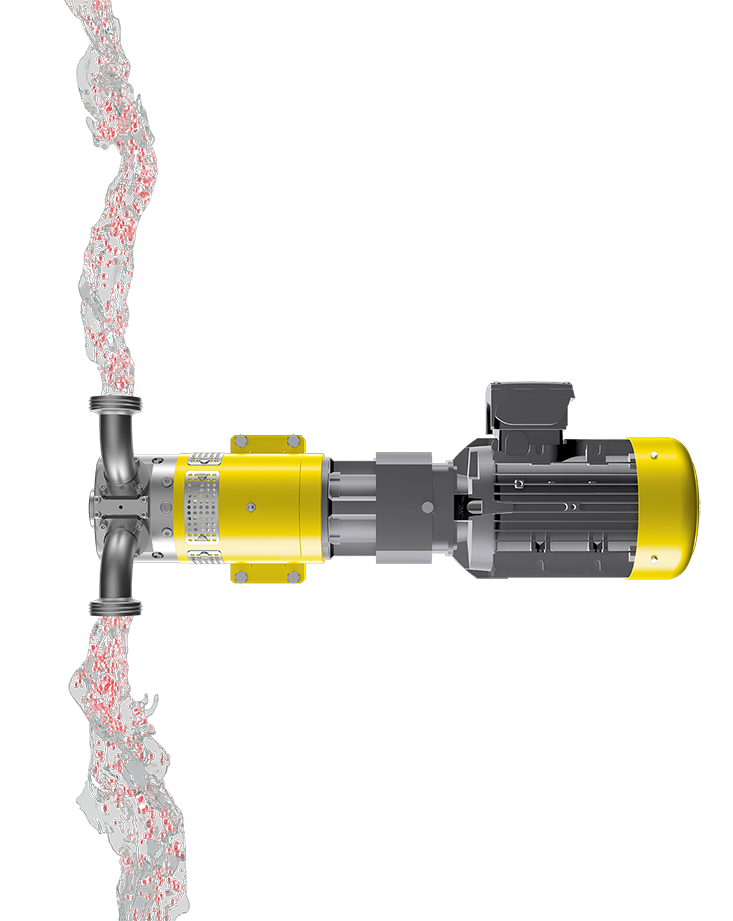

Overview of the design variants of our wobble plate pumps

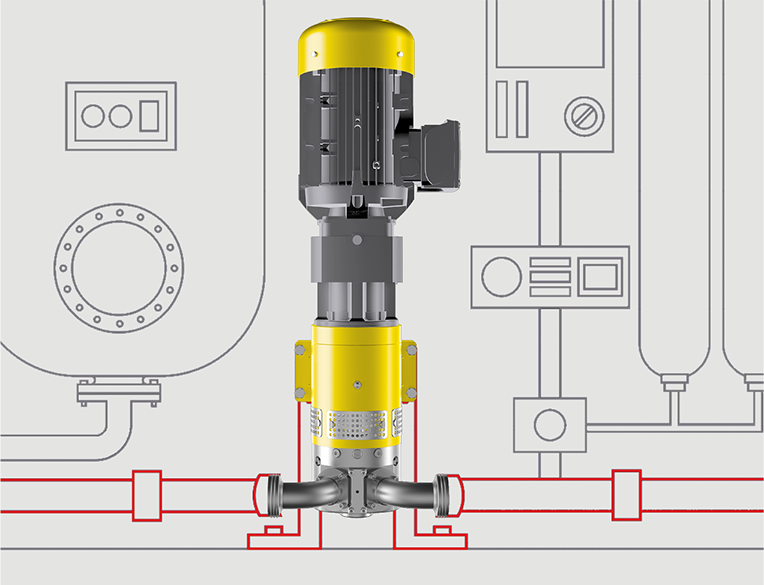

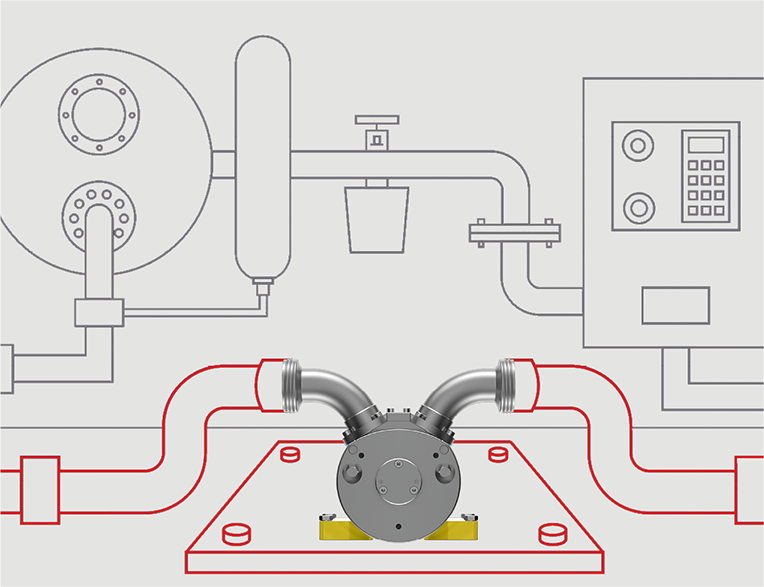

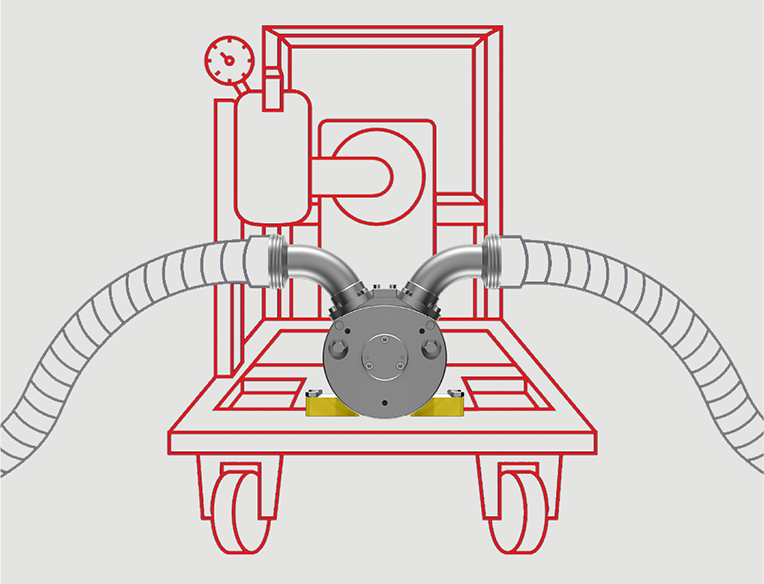

Promised and kept: Our pumps can be installed in no time at all and are quickly ready for use, without high installation costs and without any long interruptions. You enjoy pure flexibility during installation: Install our latest generation of wobble plate pumps horizontally or vertically. You can also benefit from a mobile assembly on a trolley, which offers you additional flexibility.

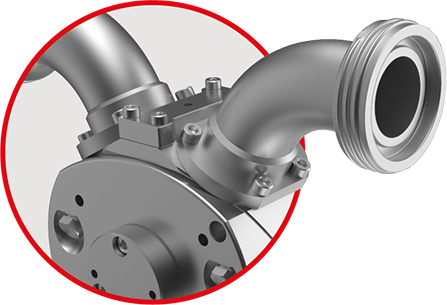

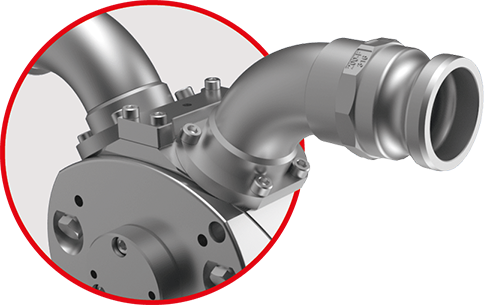

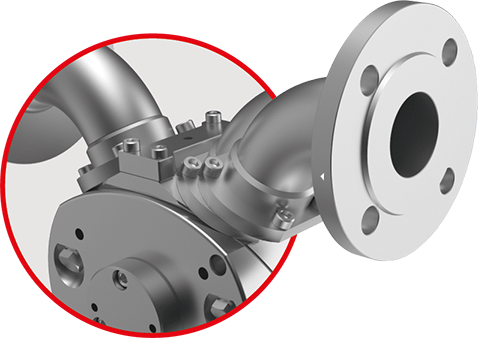

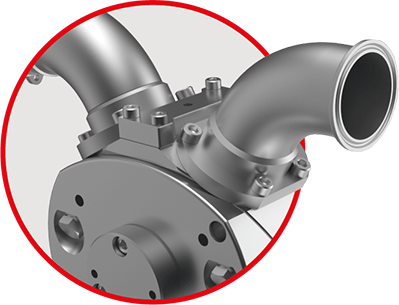

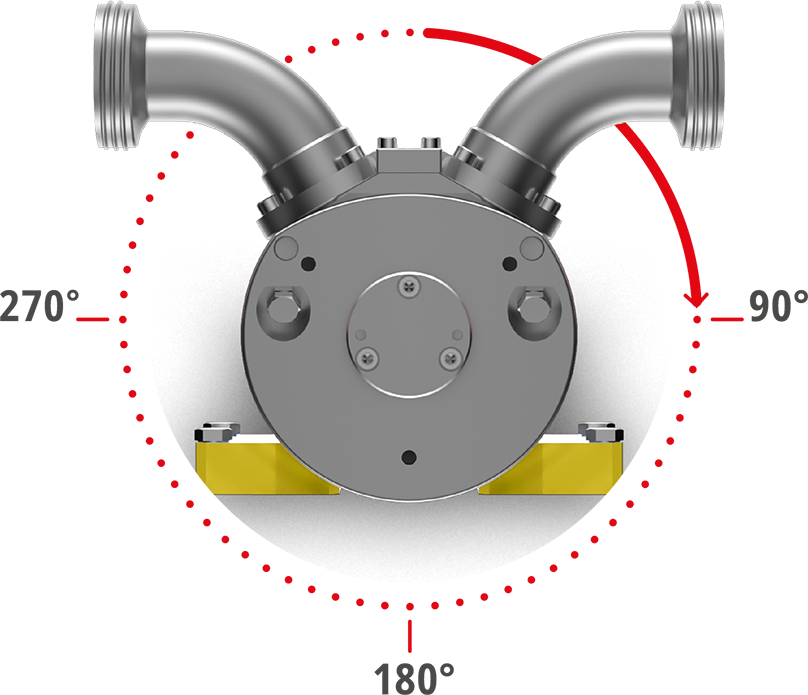

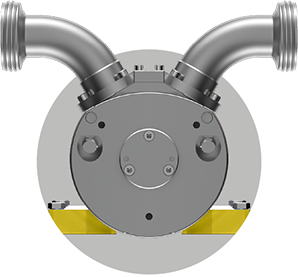

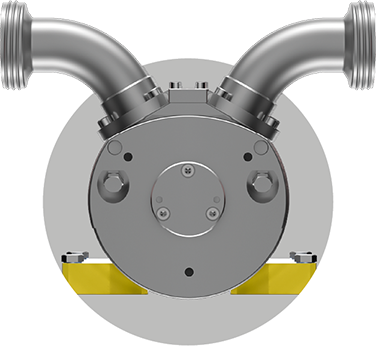

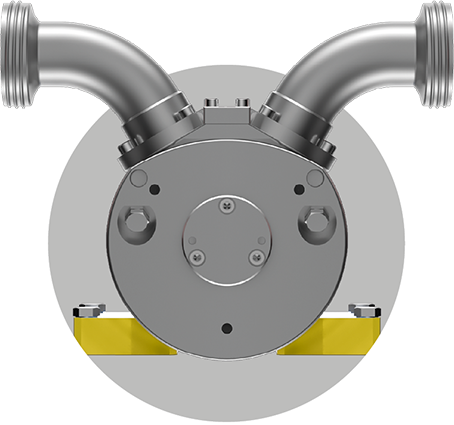

Flexibility thanks to rotatable pump head

The pump head can be rotated in simple 90 degree increments to ensure smooth adaption to existing pipelines.

Connection types

Our series offers a variety of mounting systems such as milk pipe, camlock, flange and TriClamp to meet your individual requirements.

Our wobble plate pump models in detail

In our product portfolio, you will find three standard models of the wobble plate pump, which are already pre-assembled and ready for use in stock. They cover the most common pump applications in the industry. You also have the option of customising a pump for special requirements. Our customised solutions enable you to optimally adapt the wobble plate pumps to your production processes and maximise the efficiency of your systems.

TRP015

The TRP 015 offers you an entrance into the world of wobble plate pumps. With a flow rate of 6,000 l/h, it is suitable for small to medium-sized applications.

TRP030

The TRP030 is the right choice for medium to large applications. The flow rate of this mid-range pump is 12,000 l/h.

TRP080

The TRP080 is the Goliath of our latest generation of wobble plate pumps. With a flow rate of up to 30,000 l/h, the pump is suitable for large industrial applications.

How our wobble plate pumps work

Our latest generation of wobble plate pumps utilise a proven principle. A spherical housing contains a wobble plate that is positioned at an angle on a shaft. The rotation of the shaft causes the plate to perform a characteristic wobbling movement. It continuously changes the volume of two chambers on both sides of the shaft. This creates alternating positive and negative pressure, which draws liquids into the pump and expels them through an outlet opening. An efficient and product-friendly principle that has proven its worth with highly viscous liquids such as oils, greases, paints, sealants and silicones, foodstuffs and pharmaceuticals.

Our complete range of wobble plate pumps

anfrage@lutz-pumpen.de