Residual emptying operating principle

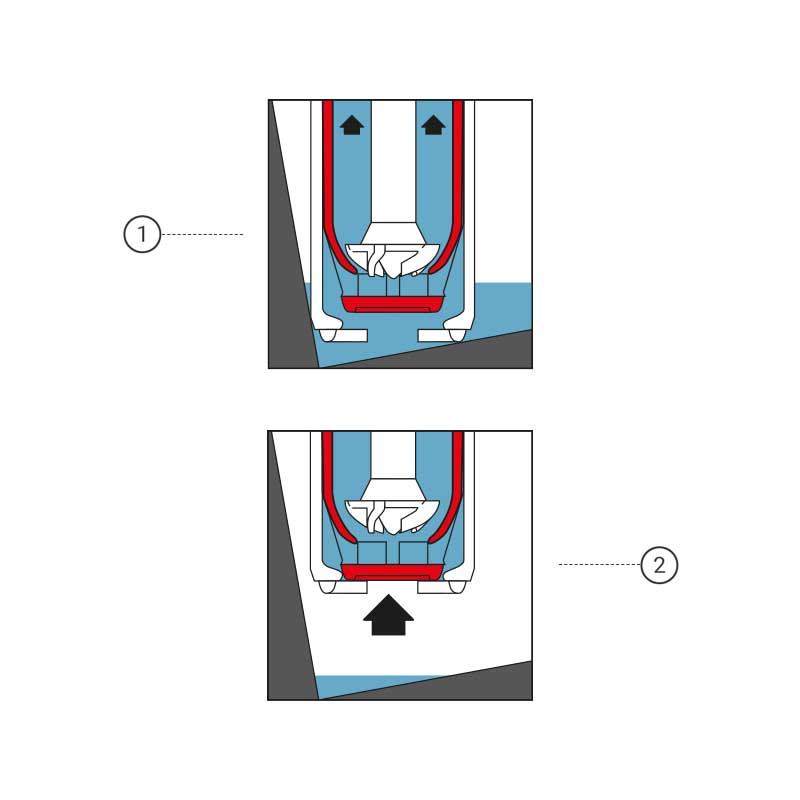

(1) When the sealing pot is open, the liquid can be pumped out.

(2) Sealing pot is closed. A return flow of the liquid is prevented, so the residual quantity can be "taken along" when the container is changed

Complete drum drainage - environmentally friendly and cost-saving

Lutz pump tubes RE in stainless steel and polypropylene. They not only protect the environment, but also your wallet. On the one hand, the liquid is used to the maximum, on the other hand, the costs for disposing of residuals are drastically reduced, as only the smallest residues remains in the containers. The pump foot is closed when the motor is running by lowering the sealing pot inside the pump tube. The sealing pot locks the pump foot and prevents the liquid that has flowed in from running back into the drum. Locking is done in the blink of an eye - via a small lever below the handwheel. Once the motor is switched off, the pump tube with the enclosed liquid can be moved to the next drum.

How does the residual emptying pump tube work?

Our complete range of waste bins

anfrage@lutz-pumpen.de