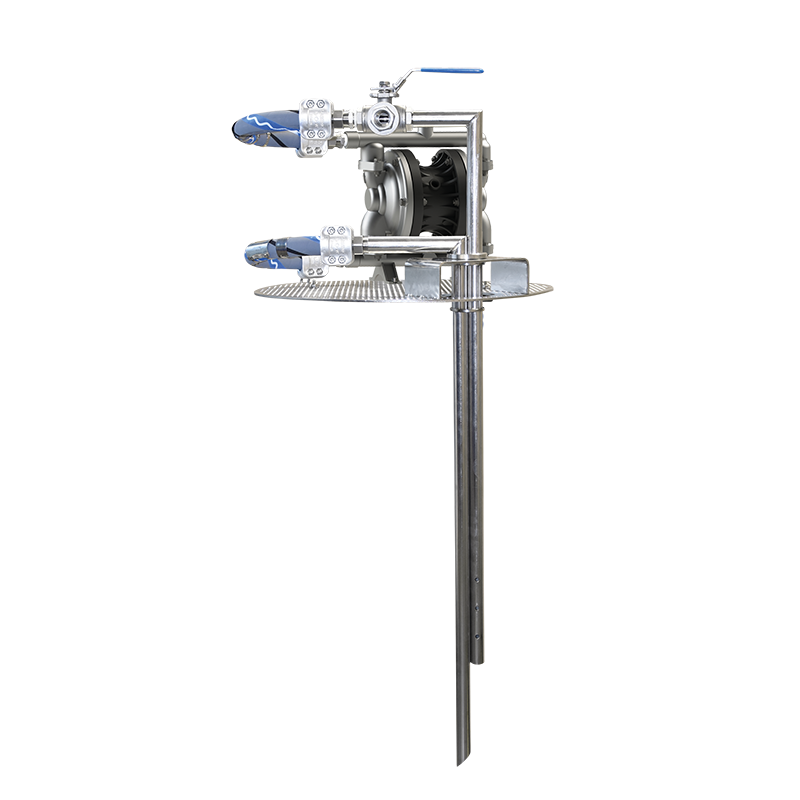

Structure of the drum pump

(1) Motor – several drive types possible

(2) Nozzle

(3) Handwheel – for mounting the motor

(4) Hose connection

(5) Drum adapter – for a safe stand

(6) Hose – in various materials

(7) Pump tube – depending on the liquid

(8) Pump foot

How is a drum pump constructed?

The Lutz drum pump consists of two main elements: Motor and pump tube. The motor serves as the drive and is responsible for the pump capacity of the various requirements. With its high-quality materials and resistance to the fluids, the pump tube ensures safe pumping. Due to the many variants of our products, we provide suitable solutions for every challenge. Our portfolio is completed by appropriate spare parts and accessories.

Select a category

Drum pumps for pumping fluids from different containers

The perfect solution and at the same time a reasonable alternative to a bucket is an electric, compressed air or battery-operated drum pump from Lutz. Knowledge, experience and a sense of responsibility are just a few arguments for placing the handling of liquids in the hands of professionals. With a Lutz drum pump anyone who transfers liquids of all kind can become a professional. Due to the variety of thin and thick, neutral and aggressive, cold and hot as , well as flammable and non-flammable liquids to be pumped, there is the demand to have the right drum pump available for every requirement.

The right drum pump for each container

Which immersion depth is needed for which container? Canisters, hobbocks, drums, IBC tanks and special containers of all kinds keep asking users this one question. Since most containers comply with a standard, this also simplifies the answer for the correct immersion depth. All standard Lutz pump tubes have been adapted to the corresponding container standards, resulting in immersioon depths of 500 mm, 700 mm, 1000 mm und 1200 mm. Lutz also has the optimum solution for special containers and pump sumps, as all pump tubes are available in individual special lengths from ~300mm to more than 3 m, which are specially manufactured for our customers.

When must an explosion-proof drum pump be used?

Explosion protection is mandatory required for flammable and highly flammable liquids, which are classified according to explosion group II (EN/IEC 60 079-0). The danger of the gases increases from explosion group II A via II B to II C. The requirements on the drum pump used for these explosion groups increase accordingly. The Lutz drum pump in explosion-protected design offers the highest possible protection when handling easily flammable, flammable substances and in explosive environments. It is designed in the material SS (stainless steel 1.4571) and Hastelloy C. It meets all international standards and regulations and complies with the directives according to Atex 2014/34/EU and IEC Ex.

Our complete range of drum pumps

anfrage@lutz-pumpen.de