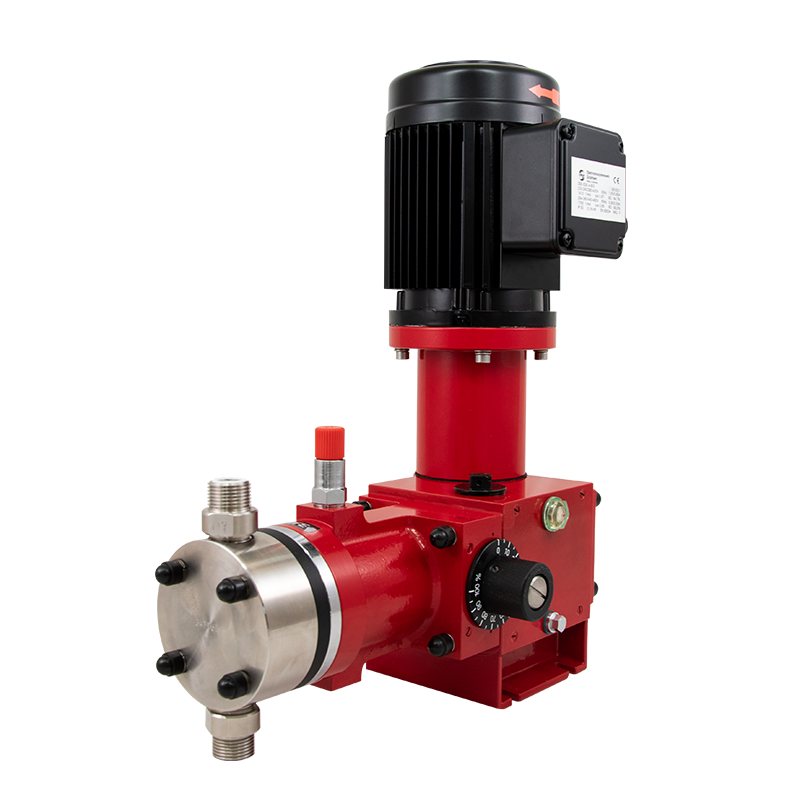

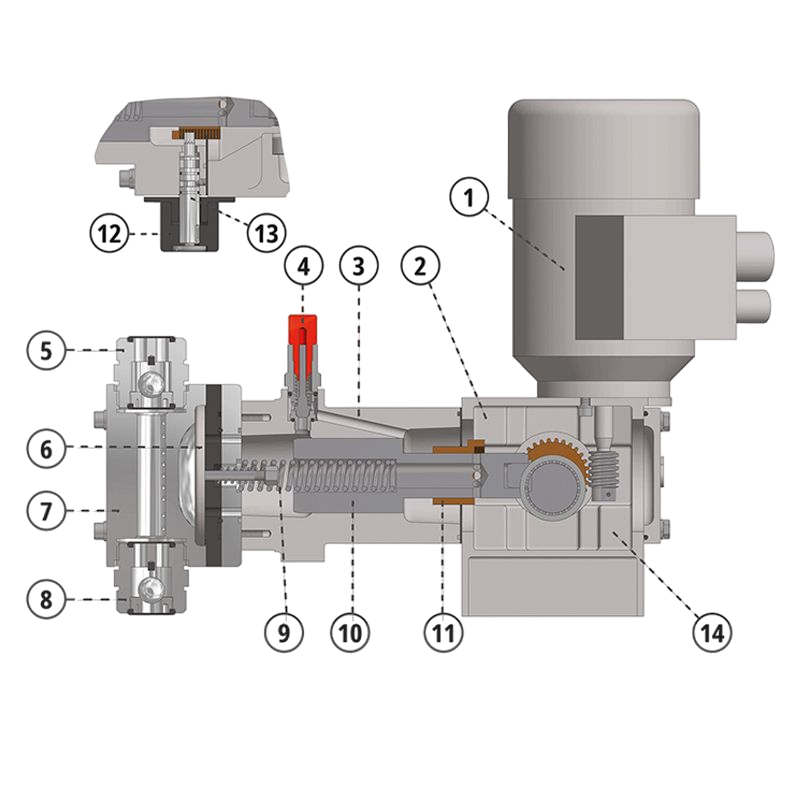

Structure of the MEMDOS KMS piston diaphragm pump

(1) Drive motor

(2) Drive

(3) Hydraulic unit

(4) Pressure relief valve

(5) Pressure valve

(6) Diaphragm

(7) Dosing head

(8) Suction valve

(9) Piston spring

(10) Piston

(11) Control slide

(12) Adjusting knop

(13) Adjusting spindle

(14) Hydraulic fluid

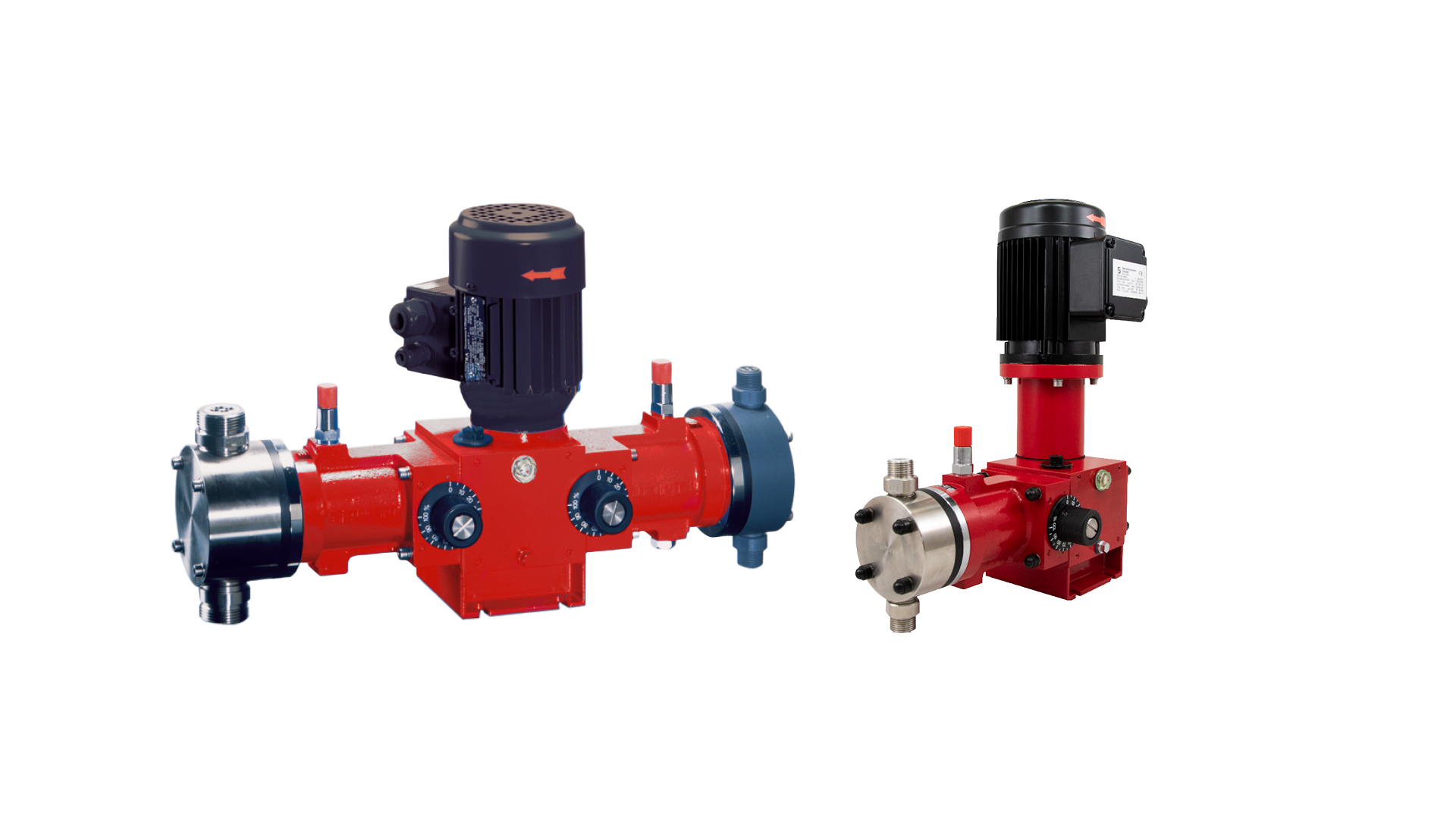

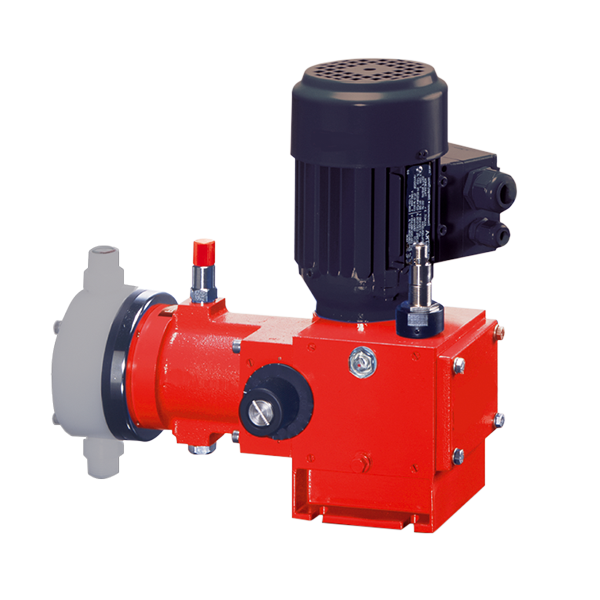

MEMDOS KMS/ZKMS

Powerhouse in a modular system

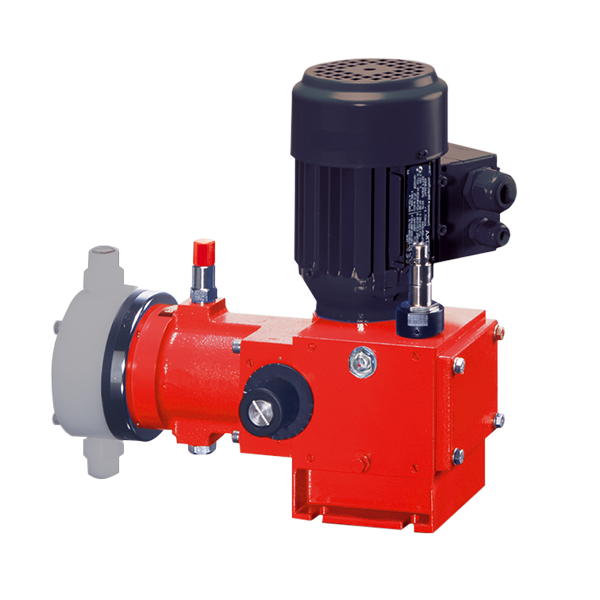

The MEMDOS KMS/ZKMS was developed in accordance with the modular principle. This offers the advantage that – depending on the problem – you can combine various pump elements and thus obtain a dosing pump that is optimally tailored to your needs.

Versatile and flexible

During the development of the MEMDOS KMS, a focus was placed on ensuring the following advantages for the user:

Ease of installation

- quick diaphragm change possible

- no zero-point correction with dismantling of the piston flange required

High flexibility

- The rational structure requires only a minimum of spare parts storage

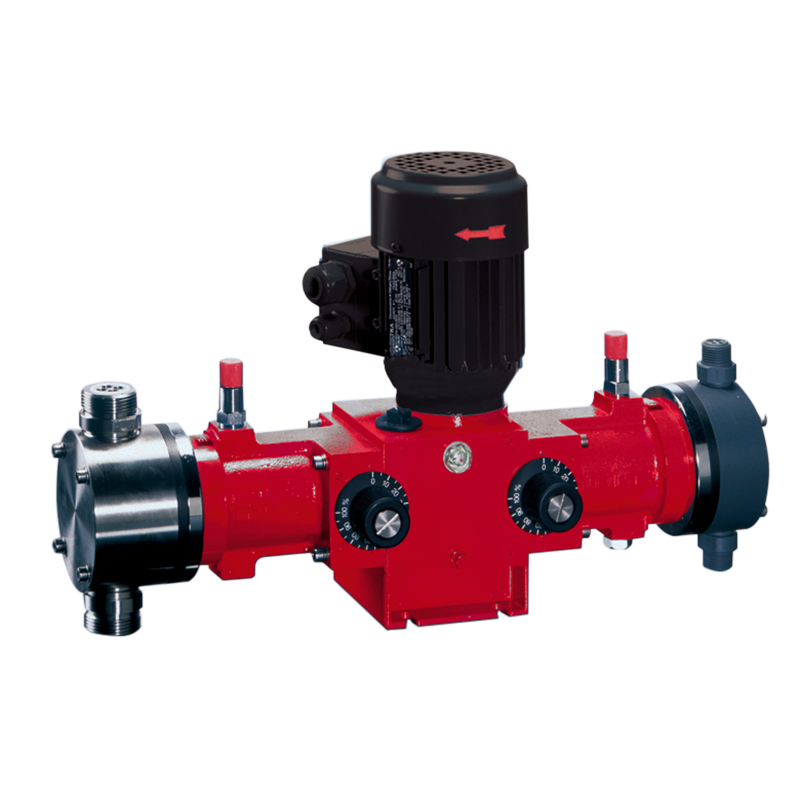

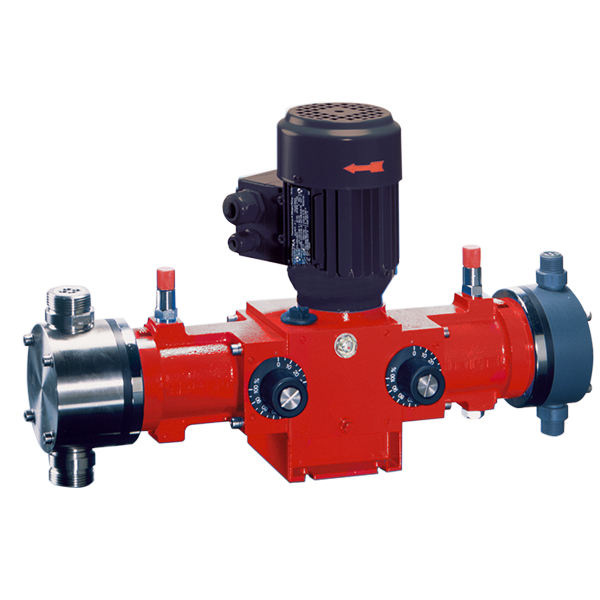

- The addition of a second dosing unit to the drive with an identical or different capacity range produces a double head pump, the MEMDOS ZKMS

- Thanks to its symmetrical form, the piston flange can be installed on the left-hand or right-hand side of the simple pump, ensuring an economical and compact system design

- Due to the installation of only four stud bolts, the dosing pump can be converted from manual stroke adjustment to electrical stroke adjustment

- For operation, motors with a multi-range voltage (220 – 240/380 – 420 V, 50 Hz; 440 – 480 V, 60 Hz) and a high protection class (IP55) and insulation class (F) are used. Special motors (ATEX) are available on request

- TÜV-checked pressure relief valves are integrated in all pumps to prevent damage to the pump and the periphery.The pressure relief valves are selected to match the pump capacity and the desired maximum pressure in the system

Our complete range of piston diaphragm dosing pumps

MEMDOS KMS

The MEMDOS KMS/ZKMS

The MEMDOS KMS/ZKMS was developed on a modular basis. This has the advantage that you can combine different pump elements depending on the problem and thus obtain a dosing pump that is optimally customised to your needs.

Features & advantages

Easy to install

Quick diaphragm change possible

No zero point correction required when dismantling the piston flange

High flexibility

Available as single or double-head pump

Standard version single pumps left-sided dosing head arrangement

Integrated overflow valves to prevent damage to the pump and peripherals

Your contact person

Lutz-Jesco | Contact

Do you have questions about dosing pumps, disinfection systems, chlorine dosing systems, system and process technology or measurement and control technology?

Our team of experts will be happy to assist you. Please send us an enquiry or call us directly.

+49 5130 5802-0

info@lutz-jesco.com