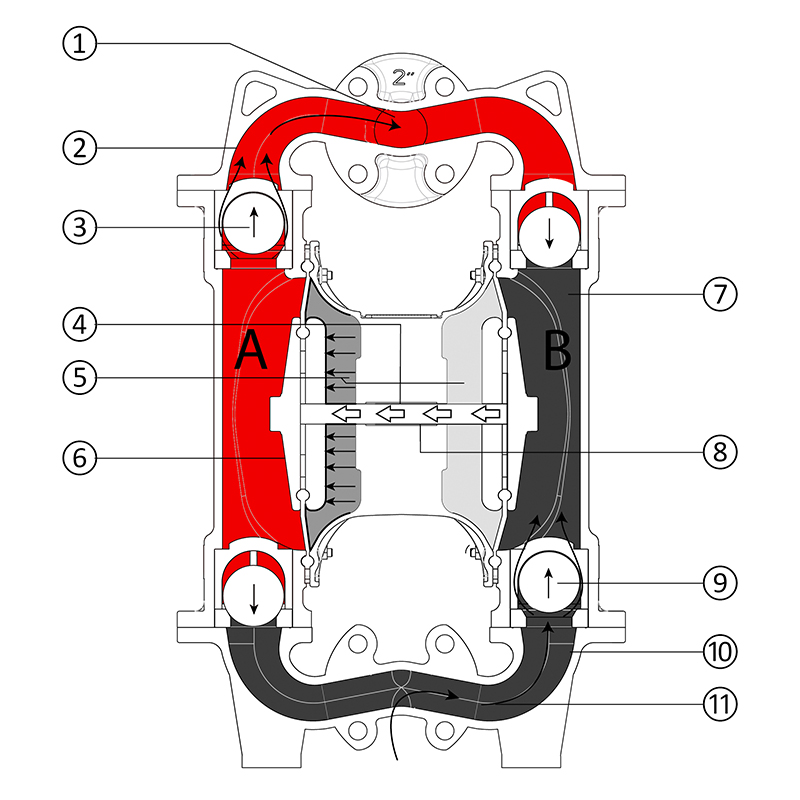

Structure of the diaphragm pump

(1) Outlet

(2) Outlet pipe

(3) Outlet check valve

(4) Air valve

(5) Air chamber

(6) Diaphragm

(7) Liquid chamber

(8) Diaphragm - connecting shaft

(9) Inlet ball valve

(10) Inlet pipe

(11) Inlet

Select a category

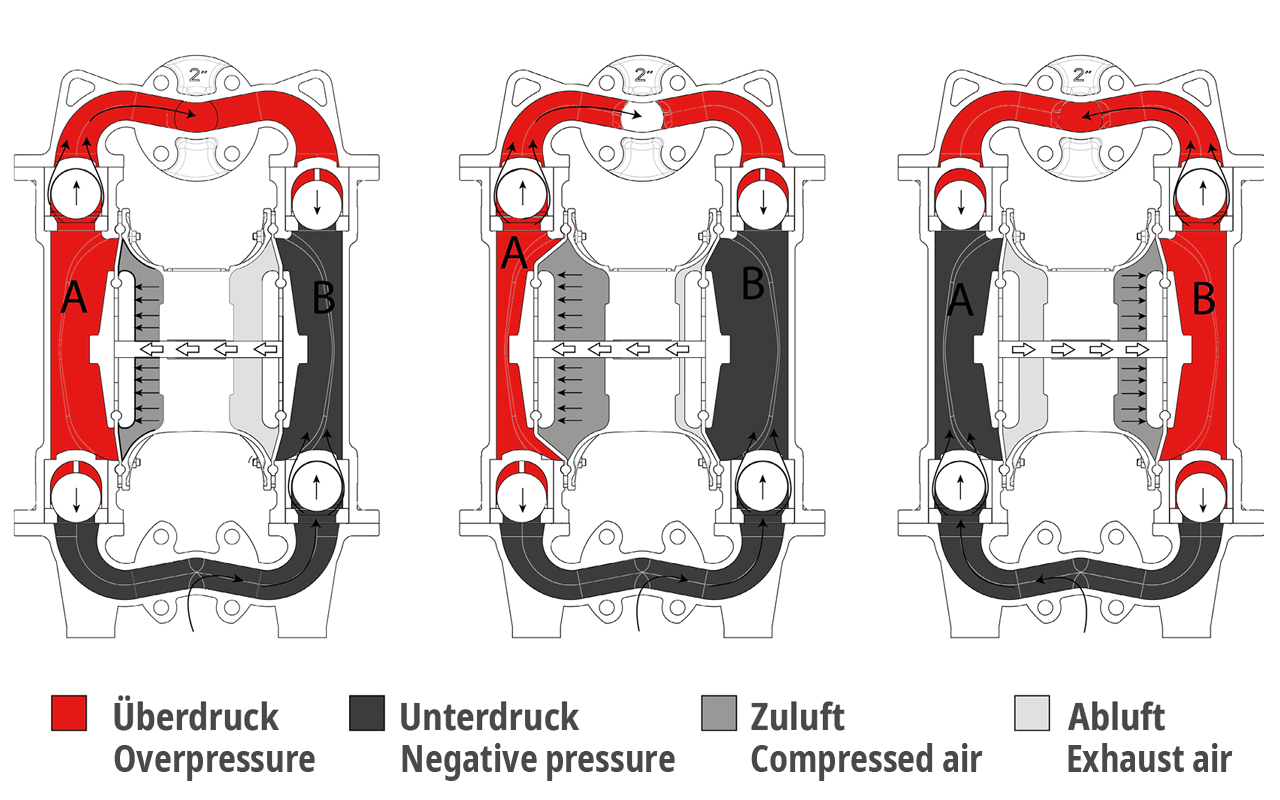

How our diaphragm pump works:

The overpressure created in the chamber (A) closes the suction valve and opens the pressure valve, allowing the liquid to enter the pressure line. At the same time, the same process takes place in reverse order in the negative pressure area of chamber (B). The pressure valve closes and the suction valve opens so that the liquid can flow in on the suction side.

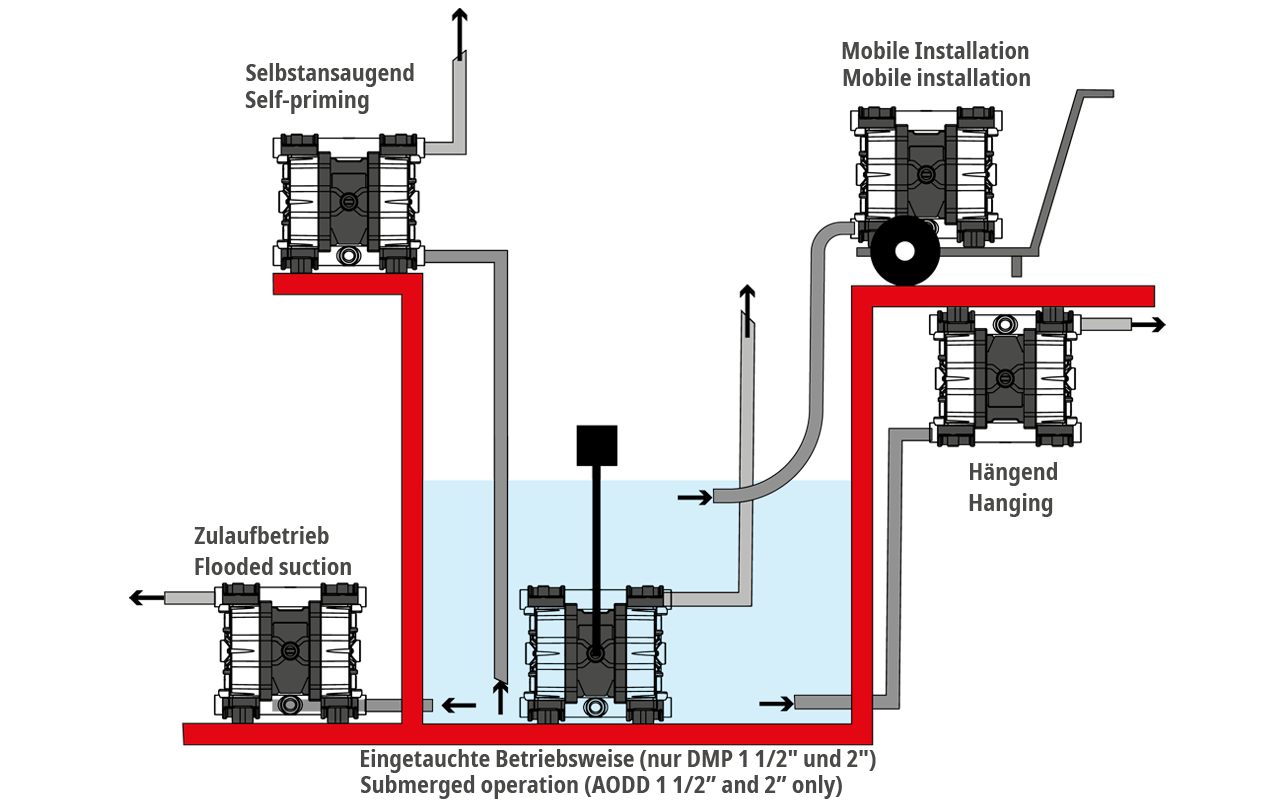

Installation options for the compressed air double diaphragm pump

Self-priming

If the suction joint is above the liquid level, the pump must suck in the pumped liquid itself. When running dry, the diaphragm pumps can self-prime up to 4.5 m wc and when the suction line is full, a suction head of up to 9 m wc can be achieved.

Submerged operation

Pumps of sizes 1 1/2” and 2” can be submerged in liquids and operated there, provided the pump material is sufficiently resistant and the air outlet is above the liquid level.

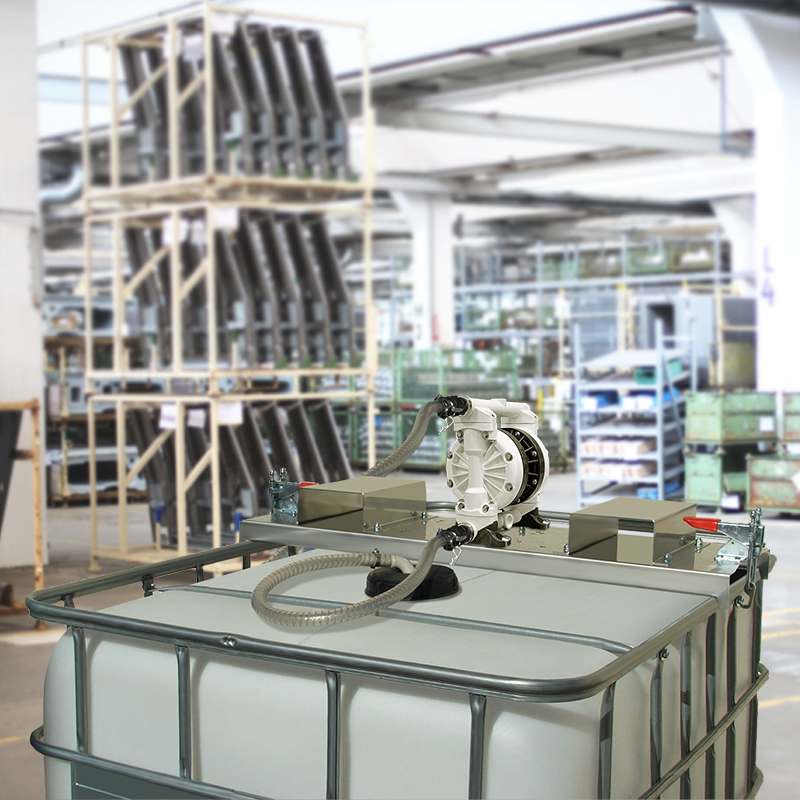

Stationary or mobile installation

The pumps can either be mounted stationary or transported as required to different application sites to empty the liquids from different containers.

Flooded suction

If the liquid level is above the suction joint, this is referred to as positive feed. If the maximum inlet pressure is exceeded, the suction line should have appropriate shut-off valves

Hanging construction

For special process requirements, the pump can also be installed in a hanging position.

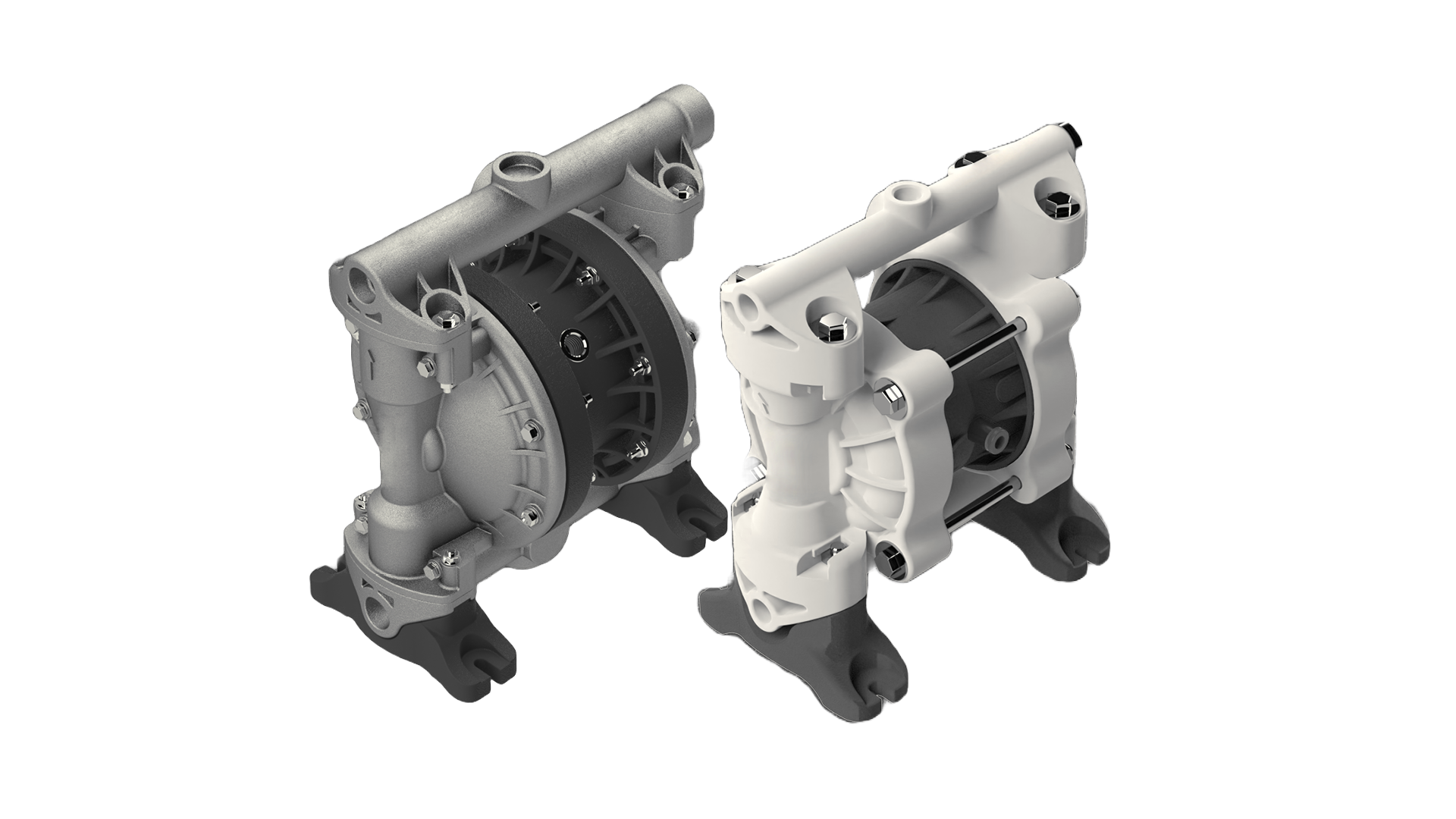

Our complete range of diaphragm pumps

anfrage@lutz-pumpen.de