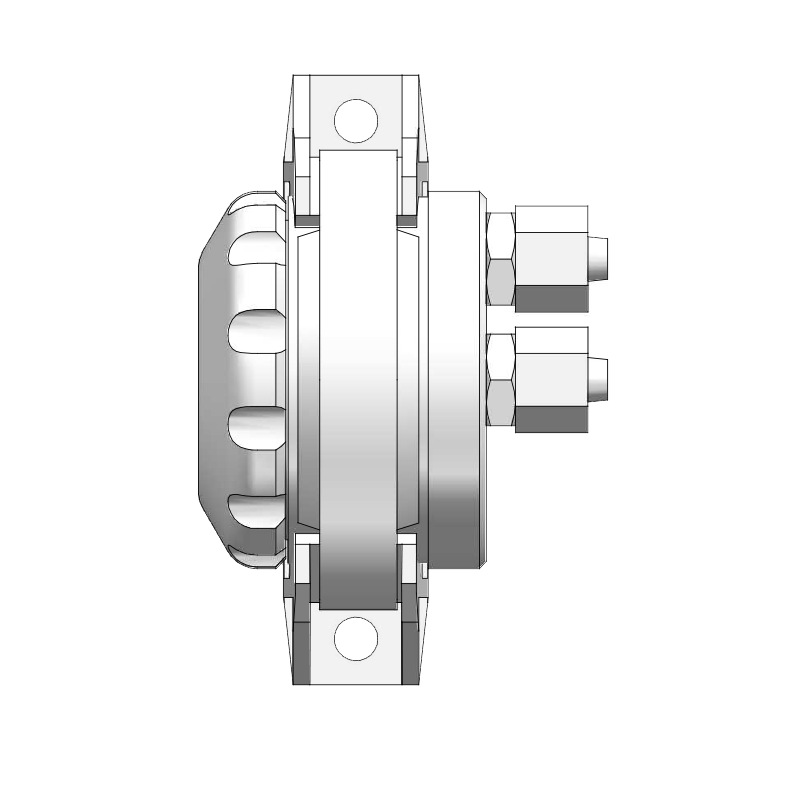

Safety blow-off valve

Modern chlorine gas dosing systems used in water treatment processes work with the vacuum procedure in accordance with DIN 19606. As the central safety component, the vacuum regulator is usually located directly on the chlorine tank valve. It ensures an operating pressure in all subsequent lines which is lower than the atmospheric pressure. This means that chlorine cannot escape, even given a leak, as the negative pressure only extracts air.

Every technical system can experience malfunctions, e.g. through soiling of the device. In such malfunctions, positive pressure can build up in the vacuum system. As such, DIN 19606 prescribes a safety blow-off valve.

Safety blowoff valve

Even given a low positive pressure, the safety blow-off valve opens and enables the chlorine gas to flow away to a targeted safe location. In the majority of cases, an activated carbon cartridge is connected, which absorbs non-hazardous quantities. With real malfunctions, the chlorine flows to the gas warning device sensor and triggers an alarm.

Features & Benefits

- Protection against positive pressure in the vacuum system

- Opening pressure of the blow-off valve approx. 30 mbar

- Materials in contact with the media PVC, FPM

- Delivery inc. wall bracket