Delivery time on request

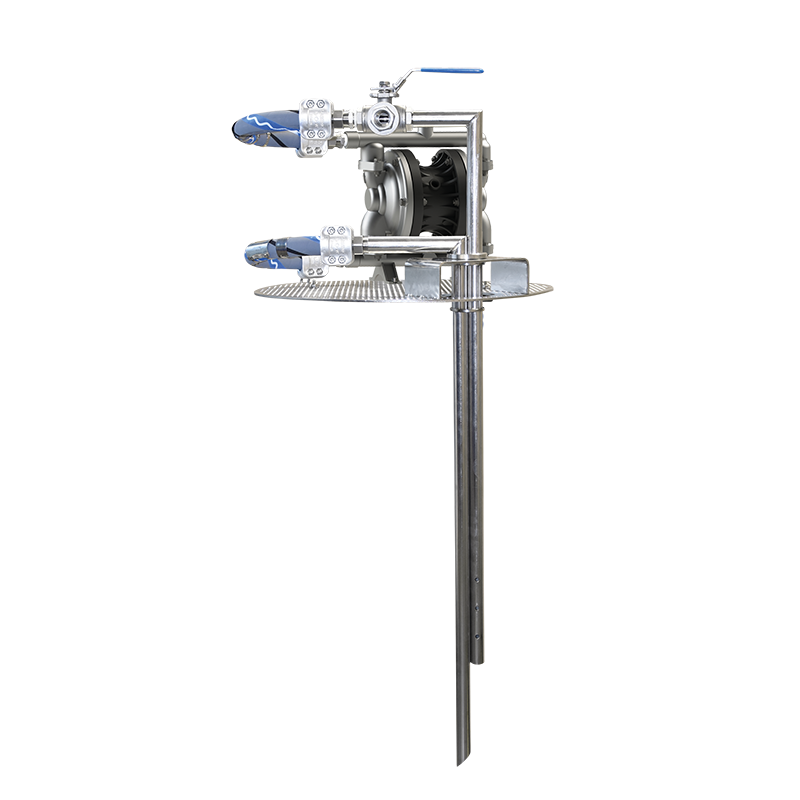

Product information "Diaphragm pump mixing system"

Description:

The new diaphragm pump mixing system with an integrated compressed air-driven double diaphragm pump is the perfect solution for liquids that need to be mixed before processing and then pumped or that also contain small solids. The mixing and pumping process takes place via a suction and mixing pipe and a 3-way valve. The pre-assembled system is ready for immediate use in just a few simple steps and is also suitable for potentially explosive liquids.

- Mixing and pumping integrated in one system

- Examples of media: Paints and varnishes, emulsions, dispersions, suspensions, water/oil mixtures, liquids with increased viscosity and solids content

Properties & advantages

- Quick installation and time saving due to easy handling

- Compact design

- Base plate offers good stability on the container lid

- Easy to insert into the 2" bunghole of the container using a balancer or overhead crane

- No additional mixer required

| Certification: | ATEX Richtlinie (ATEX Richtlinie 2014/34/EU) |

|---|---|

| Delivery rate (up to max. l/min)*: | 57 |

| Design/equipment: | Bolted version |

| Housing (material): | Stainless Steel |

| Membranes (material): | PTFE (polyvinylidene fluoride) |

| Operating pressure (max. bar): | 8,2 |

| Pumped liquid temperature (max °C): | 93 |

| Seals (material): | EPDM (ethylene-propylene-diene monomer), FPM (fluorinated rubber), NBR (nitrile butadiene rubber), PTFE (polyvinylidene fluoride) |

| Size (inch): | 1/2" |

| Solids (max. ø mm): | 3,2 |

| Suction height dry (in m): | 4,3 |

| Type: | DMP 1/2" SST SS/PTFE |

| Valve ball (material): | PTFE (polytetrafluoroethylene) |

| Valve seat (material): | Stainless steel |

* The maximum flow rate is a value determined by means of a test bench and measured with water at a liquid temperature of approx. 20 °C . The measurement is taken at the pressure joint of the pump, without hose, nozzle or flow meter. The achievable flow rate in use is lower and depends on the individual application, the liquid properties and the configuration of the pump. The max. delivery head also depends on the pump design, motor and fluid. The viscosity values are determined with oil.

** Test assembly: Medium water / diesel, flow in preferred direction, settling section 0.2 m upstream and downstream of flow meter