“We have been supporting the global metal and electrical industry for 70 years in their efforts to make all the processes involved in dosing and treating water more efficient and sustainable”, (Heinz Lutz, CEO of Lutz-Jesco GmbH).

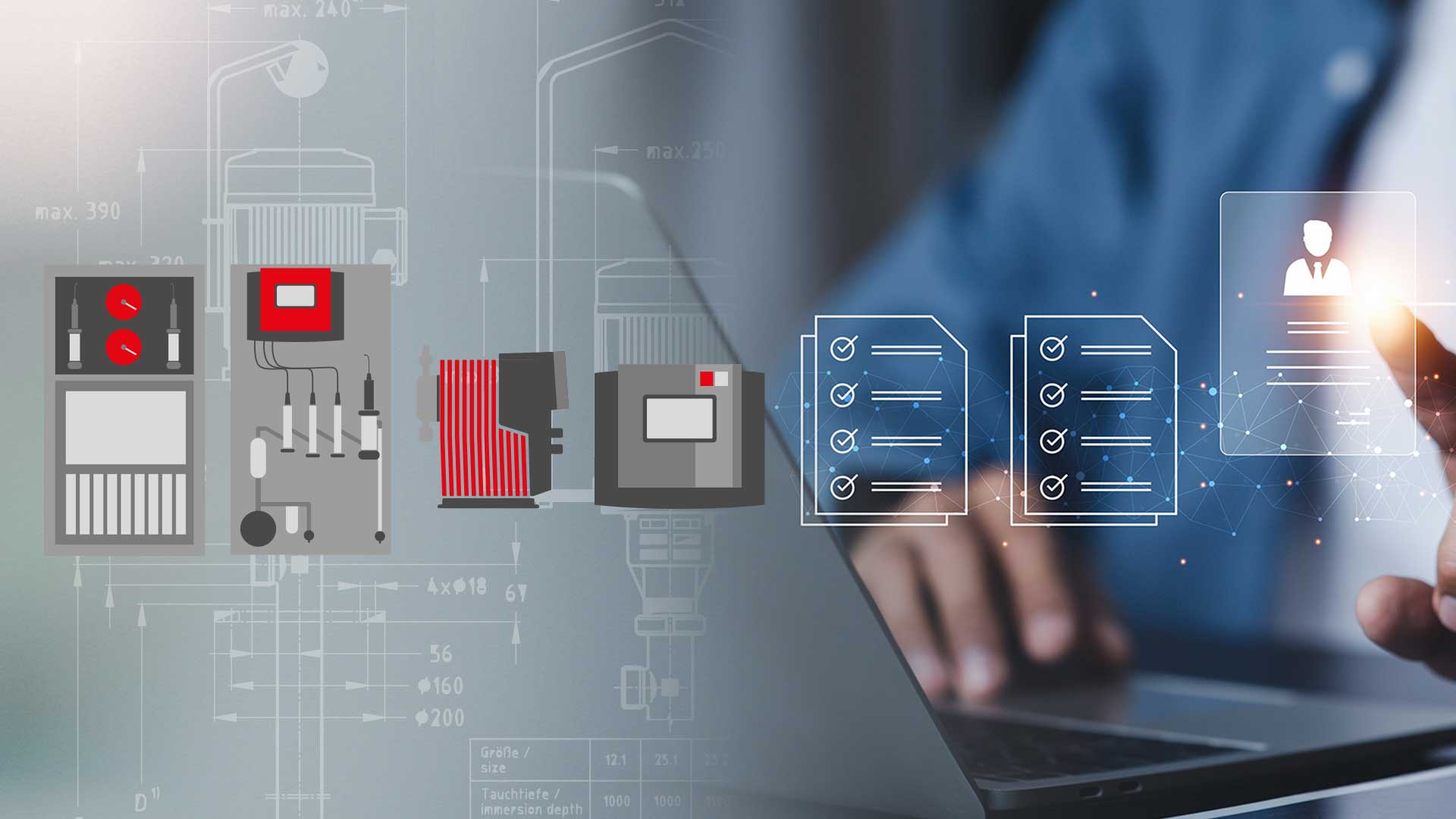

Taking dosing processes and water treatment to the next level

Lutz-Jesco supports the metal and electrical industry in their efforts to make processes in the area of dosing and water treatment more efficient. Robust and reliable dosing systems and pumps with modern measurement and control technology are deployed throughout the world to ensure the precise and safe dosing of chemicals, additives, coolants and cleaning solutions. Water treatment systems enable the effective treatment of cooling water for production processes, process water for industrial applications and wastewater from manufacturing processes. The technologies make a significant contribution to optimising operating processes and product quality.

Lower costs, protect the environment and immerse yourself in Industry 4.0

Companies in the metal and electrical industries throughout the world use Lutz-Jesco products to lower their costs, protect the environment and drive the Industry 4.0 transformation. The precise dosing systems ensure the sparing use of expensive chemicals so that users can make production more cost-effective and protect the environment. Our modern measurement and control technology systems are designed to enable quick integration into digital production environments. These advantages are becoming increasingly important in times of increasing cost pressure, stricter regulations and labour shortages.

Please contact us. We can work together to find the right solution!

From an affordable solenoid diaphragm dosing pump to our industry 4.0 compatible dosing station, more than 150 Lutz-Jesco products in thousands of variants make it possible to adapt the capacity and functionality of our devices to the specific requirements of individual locations without over-dimensioning. Contact us today to find out more about our products. Work with us to realise your customised solutions! You can reach us by telephone at xx or by e-mail at xx.

Applications for the metal and electrical industry

Products for the metal and electrical industry