„Our goal is to optimise your agricultural processes in a modern and future-proof manner”, Heinz Lutz, CEO of Lutz-Jesco GmbH

For healthy yields and sustainable cultivation methods

Cost pressure, stricter environmental regulations and demographic change pose challenges for agriculture. Modern farms therefore attach great importance to efficient, precise and safe operating processes. This applies in particular to fertilisation, irrigation, crop protection and animal feed, which increasingly need to be resource-saving, environmentally friendly and often semi-automated. Pumps and dosing systems from Lutz-Jesco contribute to healthy yields and sustainable cultivation methods by ensuring the precise dosing and distribution of chemicals, nutrients and liquid feed.

But safely, too!

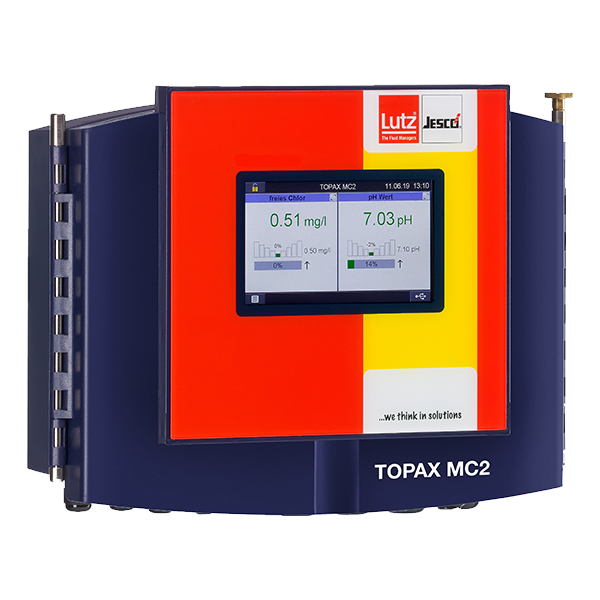

Dosing pumps and dosing systems from Lutz-Jesco comply with the high demands placed on them by the agriculture industry in terms of durability and safety. Made of resistant materials such as corrosion-resistant stainless steel and durable plastics, our products provide high resistance to extreme environmental conditions and the aggressive chemicals used in the agriculture industry. The safety mechanisms established in our systems protect both users and the environment from potential dangers.

Staying flexible!

Our wide range of products offer the right solution for every farm size and every situation in agriculture. With delivery rates from a few millilitres up to 4,400 litres per hour and a dosing accuracy of up to +- 2%, we cover the entire spectrum of agricultural applications from precision dosing to large-scale irrigation. Our systems function as stand-alone solutions and can be integrated into automated agricultural processes.Contact our experts to find the solution that best meets your needs.

Applications for the agriculture industry

Products for the agricultural industry