Overview of all Lutz products

Our complete range

MAGDOS LB

MAGDOS LB - Simple dosing pump of the latest generation!

The MAGDOS LB solenoid-driven diaphragm dosing pump is a cost-effective alternative for simple, continuous dosing tasks. It is particularly suitable for water treatment and the process industry. The MAGDOS LB is available in seven performance ranges. Double ball valves ensure precise dosing. The dosing capacity can be adjusted continuously from 0 - 100 % via the stroke frequency of the dosing pump. The MAGDOS LB is a compact solution, reduced to the most important elements for reliable dosing.

Features & advantages

Output range 0.36 - 13 l/h, up to 16 bar

Wide-range power supply 100 - 240 V, 50/60 Hz, IP65

Dosing head ventilation (plastic version)

Suitable for wall and floor mounting

Material versions PVC, PP, PVDF, stainless steel

Dosing capacity continuously adjustable from 0 - 100

CSA and UL certified

MEMDOS SMART LB

MEMDOS SMART LB - precision that inspires!The compact stepper motor diaphragm dosing pump, paired with its intelligent drive concept, combines the size advantages of a solenoid diaphragm dosing pump with the precision of a motorised diaphragm dosing pump. The MEMDOS SMART LB series is available in six performance ranges. The drive of the MEMDOS SMART LB is fully adjustable. The stroke frequency can be infinitely adjusted manually from 0 - 100 % to adjust the dosing capacity.

Features & advantages

Capacity range 2.4 - 30.7 l/h, up to 20 bar

Power supply 100 - 250 V, 50/60 Hz, protection class IP65, power consumption 25 W

Microprocessor-controlled drive

Integrated dosing head ventilation (only MEMDOS SMART LB 2, LB 5 and LB 10 with plastic dosing head)

Suitable for wall and floor mounting

Material versions PVC, PP, PVDF and stainless steel

Stroke frequency continuously adjustable from 0 - 100

Enable input for external start/stop

MAGDOS LD

MAGDOS LD - Easy handling and space-saving!

The MAGDOS LD plays an important role in the reliable and precise dosing of liquids in process sequences and is available in seven performance ranges. Double ball valves ensure exact dosing. The stroke frequency can be adjusted manually or via external control contacts to adapt the dosing capacity.

The compact dosing pump can be integrated into any dosing system in a very space-saving manner thanks to its minimal mounting surface and can also be installed in three different positions, upright or horizontal, without the need for additional aids. left or right orientated on the wall.

Features & advantages

Output range 0.36 - 13 l/h, up to 16 bar

Power supply 230 V ±10 %, 50/60 Hz, IP65 or 115 V ± 10 %, 50/60 Hz, IP65

Dosing head ventilation (plastic version)

Suitable for wall and floor mounting

Material versions PVC, PP, PVDF, stainless steel

Stroke frequency precisely adjustable with keypad

Graphic display

Pulse input (overshoot and undershoot)

Level input with pre-alarm and main alarm

Enable input for external start/stop

Calculation wizard for pulse operation available online

CSA and UL certified

MAGDOS LP

MAGDOS LP - Easy handling and space-saving!

The MAGDOS LP is available in seven output ranges. Double ball valves ensure precise dosing. To adjust the dosing capacity, the stroke frequency can be adjusted manually, via external control contacts or via a 0/4 - 20 mA signal.

The MAGDOS LP is also available with an optional Ethernet interface. The network connection makes it possible to control the stroke frequency and the number of strokes. In addition, all fault messages can be transmitted in the opposite direction.

Features & advantages

Output range 0.36 - 13 l/h, up to 16 bar

Wide-range power supply 100 - 240 V, 50/60 Hz, IP65

Dosing head ventilation (plastic version)

Suitable for wall and floor mounting

Material versions PVC, PP, PVDF and stainless steel

Stroke frequency precisely adjustable with keypad

Graphic display with multilingual menu

Analogue input and pulse input (overshoot and undershoot)

Level input with pre-alarm and main alarm

Enable input for external start/stop

Display of flow rate in various units

Limitation of the maximum flow rate possible

Energy-saving mode "Eco-Mode" possible

Stroke feedback output

Alarm relay output

Batch dosing with interval and timer function

Dosing control input

Diaphragm rupture detection and signalling (optional)

Ethernet interface (optional)

CSA and UL certified

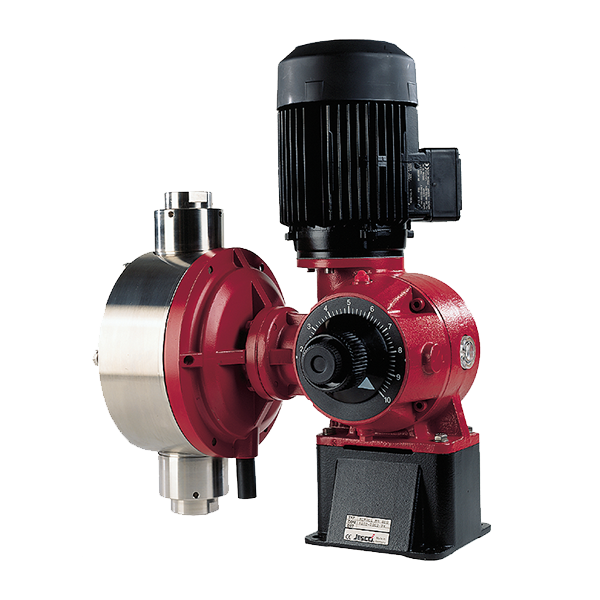

MEMDOS LA

MEMDOS LA - technology that makes waves!

The MEMDOS LA motorised diaphragm dosing pump sets standards with its robust and sophisticated drive concept and ease of operation. The MEMDOS LA series is available in two sizes and covers a performance range of 4 - 1020 l/h. Thanks to a robust tappet drive with manual or automatic capacity adjustment via external current signals, the pumped media, e.g. Acids, alkalis, precipitants and flocculants, reliably and precisely dosed.

Properties & advantages

Output range 4 - 1020 l/h, up to 16 bar

Power supply 120 V, 208 V or 230 V, 50/60 Hz

Material versions PVC, PP, PVDF and stainless steel

Stroke frequency manually adjustable via potentiometer

Enable input for external start/stop

Analogue input 0/4 - 20 mA

Level input with one switching point

Analogue output 0/4 - 20 mA

Alarm relay output

Stroke feedback output

Double diaphragm system (optional)

MEMDOS SMART LP

MEMDOS SMART LP - precision that inspires!The compact stepper motor diaphragm dosing pump, paired with its intelligent drive concept, combines the size advantages of a solenoid diaphragm dosing pump with the precision of a motorised diaphragm dosing pump. The MEMDOS SMART LP series is available in six performance ranges. The drive of the MEMDOS SMART LP is fully adjustable. A version with an Ethernet-based MODBUS interface is available for integration into sophisticated automation networks.

Features & advantages

Capacity range 2.4 - 30.7 l/h, up to 20 bar

Power supply 100 - 250 V, 50/60 Hz, protection class IP65, power consumption 25 W

Microprocessor-controlled drive

Integrated dosing head ventilation (only MEMDOS SMART LP 2, LP 5 and LP 10 with plastic dosing head)

Suitable for wall and floor mounting

Material versions PVC, PP, PVDF and stainless steel

Stroke frequency precisely adjustable with keypad

Graphic display with multilingual menu

Analogue input and pulse input (overshoot and undershoot)

Level input with pre-alarm and main alarm

Enable input for external start/stop

Display of flow rate in various units

Limitation of the maximum flow rate possible

Diaphragm change programme

2 slow motion modes for dosing viscous media

Stroke feedback output

Alarm relay output

Batch dosing with interval and timer function

Dosing control input

Diaphragm rupture detection and signalling (optional)

Ethernet interface (optional)

MEMDOS LP

MEMDOS LP - technology that makes waves!The MEMDOS LP is used when the pump needs to be integrated into control systems or control loops. A version with an Ethernet-based MODBUS interface is available for integration into sophisticated automation networks. Thanks to a robust tappet drive with manual or automatic capacity adjustment, the pumped media, e.g. acids, alkalis, precipitants and flocculants, are dosed reliably and accurately. The MEMDOS LP is also available with a double diaphragm system on request.

Features & advantages

Capacity range 4 - 1020 l/h, up to 16 bar

Power supply 230 V ± 5%, 50/60 Hz

Material versions PVC, PP, PVDF and stainless steel

Stroke frequency can be set with high precision using the keypad

Graphic display with multilingual menu

Analogue input 0/4 - 20 mA

Pulse input (overshoot and undershoot)

Level input with pre-alarm and main alarm

Enable input for external start/stop

Display of the flow rate in various units

Limitation of the maximum delivery rate possible

Stroke feedback output

Batch dosing with interval and timer function

Dosing control input

Alarm relay output

Analogue output 0/4 - 20 mA

Diaphragm rupture detection and signalling (optional)

Double diaphragm system (optional)

Ethernet interface (optional)fully adjustable stepper motor drive

Dry material feeder

Optimum dosing of pourable substances Dry material feeders are used to precisely dose the pourable substances required in chemical and process engineering. Dosing is possible if the particles of the substance are fine as dust, pellets, flakes or short fibres. The devices are volumetrically conveying and equipped with dosing screws (screw spindles) for material transport. They make no reference to the dosed mass. Therefore, it must be taken into account during use whether the bulk density is permissible for the process or must be changed by suitable measures. The bulk density influences the amount of material that is transported per dosing cycle, as it determines how densely the material is packed in the feeder. Exact knowledge of the bulk density is therefore crucial to ensure consistently precise dosing.Properties of our dry material feedersreliable and precise dosing of, for example, burnt lime, polyelectrolytes or activated carbon.

Features & benefits

Volumetric screw feeder

Delivery rate 4 - 2,650 dm³/h

Dosing screws made of aluminium (3.1645)

Housing material stainless steel (1.4571) or polypropylene (PP)

Accessories such as storage hopper, rebalancing motor, etc. available"

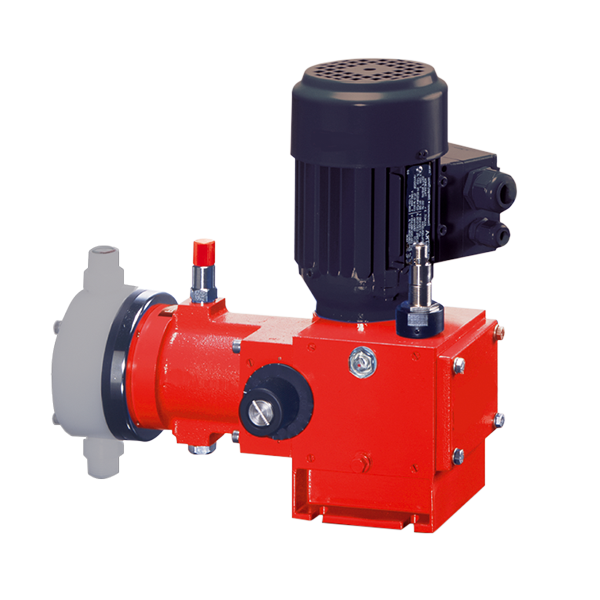

MEMDOS LB

MEMDOS LB - technology that makes waves!

The MEMDOS LB is a motorised diaphragm dosing pump that is used when no control system is required for constant dosing. Thanks to a robust tappet drive with manual or automatic power adjustment, the pumped media, e.g. acids, alkalis, precipitants and flocculants, are dosed reliably and accurately.

To adjust the dosing capacity, the stroke length can be adjusted mechanically or the speed of the three-phase motor can be controlled via a separate frequency converter. The MEMDOS LB is also available with a double diaphragm system on request.

Features & advantages

Capacity range 4 - 1020 l/h, up to 16 bar

Power supply 120 V, 230 V or 400 V

Material versions PVC, PP, PVDF and stainless steel

Stroke length infinitely adjustable from 0 - 100

Wide range of three-phase and alternating current motors

ATEX versions for zones 1 and 2 possible

Suitable for frequency converter operation

Double diaphragm system (optional)

Automatic stroke length adjustment (optional)

MEMDOS SMART LDX

MEMDOS SMART LDX - dosing chemicals reliably

With the new stepper motor technology of the MEMDOS SMART LDX, even the smallest quantities can be dosed with high precision.

The new generation offers a variety of attractive solutions for demanding and complex dosing tasks. The LDX series is available in eight performance ranges.In addition, the new generation of smart pumps has a full-colour 3.5-inch touchscreen display for simple and safe operation,and for even more flexibility, the smart pumps can be ordered ex works with a left- or right-hand display.

Graphic display with multilingual menu

Display of the flow rate in 7 different units

Paper base for standard or wall mounting

Password protection and adjustable ranges

Alarm status shown in colour on the display

Calibration mode

Removable display (optional)

Display position rotated (optional)

Available on request: Multiple pumps can be operated via one display

Manual control, 0 - 100 %

Pulse control, constant or dynamic

Enable input (external start / stop)

Level input with pre- and main alarm

Pulse input, overspeed and underspeed

Pulse output: stroke feedback

MEMDOS MR

MEMDOS MR/ZMR - Powerful motor-driven diaphragm dosing pump!Diaphragm dosing pumps in the MEMDOS MR series have been developed for a wide range of dosing technology applications. The dosing pumps are therefore used in the industrial sector, in process engineering and particularly frequently in water treatment and waste water treatment.

Features & advantages

robust, durable

Available as a single or double-head pump

Standard version single pumps left-sided dosing head arrangement

Capacity range 440 - 990 l/h, up to 5 bar

Double-head pumps diagonal dosing head arrangement

Capacity range 55 - 980 l/h per dosing head, up to 10 bar

Different materials and output ranges can be combined

Stroke length manually adjustable from 0 - 100

Electric actuator to control the stroke length (optional)

Materials: PVC, PP, PVDF and stainless steel

Suitable for frequency converter operation

Motors available in AC and three-phase versions

Peristaltic pump 2.8 litres

The 2.8 l/h peristaltic pump is used in water treatment wherever low-pulsation dosing at low delivery pressures is required. Compared to diaphragm dosing pumps, peristaltic pumps are characterised by their insensitivity to gas bubbles in the medium. Typical applications include the dosing of chlorine bleach, hydrogen peroxide and hydrochloric acid, but also the dosing of flocculants or cleaning agents, for example.

Features & advantages

Flow rate 2.8 l/h, up to 1.5 bar

Rotor mounted on bearings on both sides

Spring-loaded pressure rollers

Hose change without tools

Mounting on profile rail

Drainage connection

ChlorStop

The purpose of the ChlorStop pressure safety shut-off valve is to interrupt the chlorine gas supply or the chlorine gas outlet directly from a chlorine tank immediately after a chlorine alarm or the detection of excess pressure (e.g. by the PLUS safety blow-off valve). ChlorStop is mounted directly on the tank valve. An electromagnet closes the valve within a very short time. This ensures a high level of safety and prevents further chlorine gas leaks.

Features & advantages

Interruption of the chlorine gas supply directly from a chlorine tank valve

Shortest closing time due to electromagnets

Direct connection e.g. possible for a chlorine vacuum regulator

Suitable for gaseous chlorine

Optional control unit for simultaneous closing of up to 12 valves

Simple commissioning

Simple and space-saving installation

Low maintenance effort

for chlorine gas in accordance with DIN EN 15363 and 937

MEMDOS SMART LD

MEMDOS SMART LD - precision that inspires!The compact stepper motor diaphragm dosing pump, paired with its intelligent drive concept, combines the size advantages of a solenoid diaphragm dosing pump with the precision of a motorised diaphragm dosing pump. The MEMDOS SMART LD series is available in six performance ranges. The drive of the MEMDOS SMART LD is fully adjustable. The dosing capacity can be adjusted by manually setting the stroke frequency or using external control contacts.

Features & advantages

Capacity range 2.4 - 30.7 l/h, up to 20 bar

Power supply 100 - 250 V, 50/60 Hz, protection class IP65, power consumption 25 W

Microprocessor-controlled drive

Integrated dosing head ventilation (only MEMDOS SMART LD 2, LD 5 and LD 10 with plastic dosing head)

Suitable for wall and floor mounting

Material versions PVC, PP, PVDF and stainless steel

Stroke frequency precisely adjustable with keypad

Graphic display

Pulse input (overshoot and undershoot)

Level input with pre- and main alarm

Enable input for external start/stop

Calculation wizard for pulse operation available online

EASYPRO

The central components of the EASYPRO water sampling stations

Our water sampling stations set new standards in the monitoring and control of liquid processes. Each model is based on a carefully developed base plate, equipped with a variety of specific components. These components are precisely selected to ensure optimum functionality and performance in various industrial applications. Components of the EASYPRO

Base plate

TOPAX® MC single/multi-channel controller or TOPAX® L single-channel controller

Measuring cells and measuring cell fittings

Sample water filter

Flow monitor

DFR 45 flow controller with sample water tapping point and built-in temperature sensor

Inlet and outlet tap

Holder for buffer solutions for adjusting the measuring cells

Multicoloured LEDs

Possible measurement inputs of the industrial water sampling stations

Peracetic acid

Bromine

Free chlorine

Chlorine dioxide

Total chlorine

Conductivity

ozone

Turbidity

Dissolved oxygen

pH value

Redox value

Chlorite

Hydrogen peroxide

Temperature

Discover the EASYPRO water sampling station models

With the EASYPRO, you get a fully customised system for monitoring and controlling various water parameters in your industrial installation. The TOPAX® single or multi-channel controller installed on the EASYPRO continuously measures the water parameters and keeps them within the target range. It offers the option of controlling a large number of actuators and final control elements and is characterised by its very simple and intuitive operation. The multi-coloured LEDs provide a visual warning if the water parameters leave the setpoint range. LED illumination of the fittings

Monitoring and control of various water parameters

Continuous recording of water parameters

with cover (optional)

Compact design

including TOPAX® MC single/multi-channel controller or TOPAX® L single-channel controller

Individually configurable system thanks to modular design

Low water consumption

Plug-in system for water connections

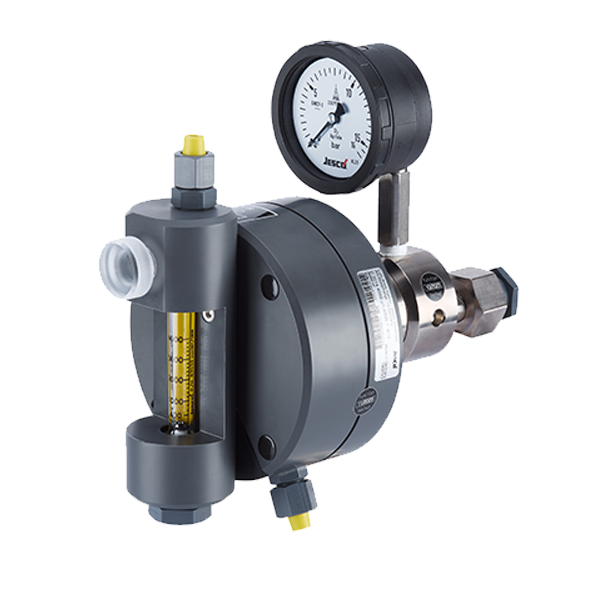

Vacuum regulator C 2214

The C 2214 is designed for individual operation. For use on gas drums, a heated droplet separator is optionally available on the pressure side in the inlet valve of the C 2214. A safety blow-off valve is integrated and prevents an impermissible increase in pressure in the downstream vacuum line system. The quantity of gas dosed can be optimally adjusted on the C 2214 using a dosing valve and flow meter.

Features & advantages

Throughput capacity with chlorine gas: up to 4 kg/h

Residual pressure protection: Prevents the chlorine cylinder from being completely evacuated to prevent corrosion caused by moisture in the air

Filter: To protect the valve from dirt particles from the chlorine cylinder or the connection area

Cylinder pressure gauge: For displaying the pressure in the chlorine tank

Integrated safety blow-off valve

Flow meter with manual setting

Gas filter

Compact design

Available with all standard gas connections

EASYPURE Powder & Liquid

EASYPURE Powder & Liquid

three-chamber system

Reliable polymer preparation station

Processing of powder and liquid polymers

Convenient operation

Integrated control in the control cabinet

Multilingual operating display

Manual and automatic operation

fill level monitoring

Withdrawal volume up to 10000 l/h

EASYCON GW

A versatile partner

To protect people and the environment, the operation of systems with hazardous gases is associated with the fulfilment of high safety requirements. Monitoring of the room air by means of gas warning devices, in which the increased concentration of gases is registered in the shortest possible time and an alarm is triggered if alarm thresholds are exceeded.

Typical applications for such gas detectors are chlorine gas rooms in swimming pools or waterworks, as well as industrial installations containing ozone and other hazardous gases.

Features & advantages

For use with chlorine gas, chlorine dioxide and ozone

Compact wall-mounted housing

Up to 4 sensors and up to 4 additional temperature sensors

Two freely adjustable alarm thresholds per alarm sensor

3 - 9 potential-free relay outputs

4 analogue outputs 0/4 - 20 mA

Large colour touch display

Data storage on a USB stick

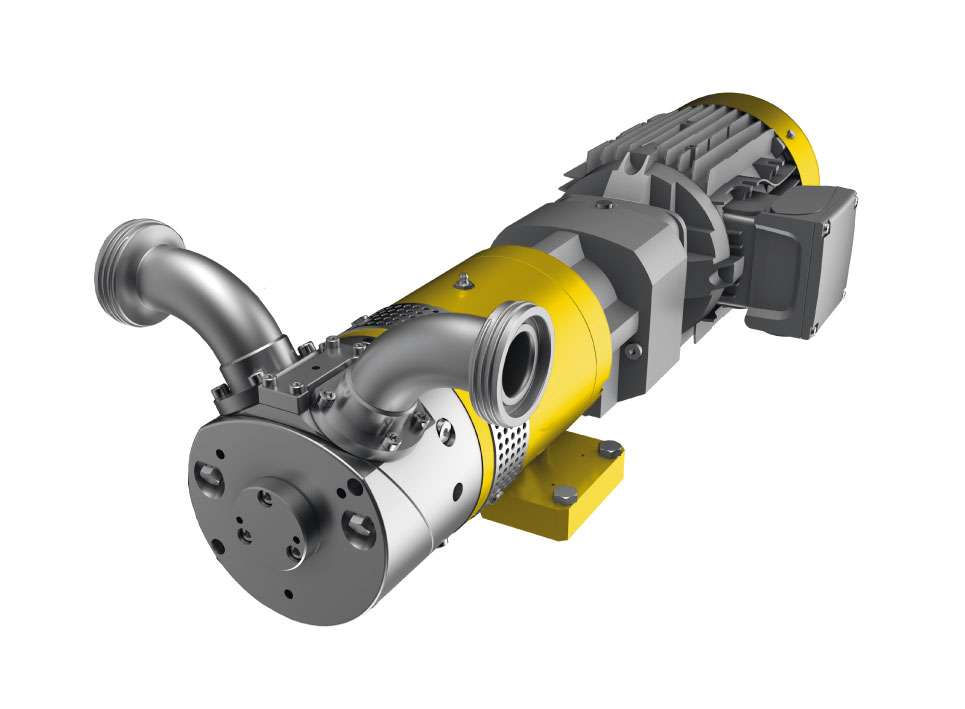

Wobble plate pump - TRP015 series

Suitable for small to medium applications

The entry-level version into the world of wobble plate pumps

The TRP015 wobble plate pumps series is your ideal solution for small to medium-sized applications in a wide range of industries. With a flow rate of up to 6,000 l/h and a delivery pressure of up to 10 bar, this model is perfect for entering the world of gentle and efficient pumping technology. Whether in the paint and coatings industry, the sealants and adhesives industry, the pharmaceutical industry, the cosmetics industry, the oil industry or the food industry - the TRP015 offers reliable performance for demanding processes.

Motor power: up to 3 kW

Diameter: 150 mm Length: 316 mm (plus motor and gearbox)

Weight: 45 kg (incl. motor and gearbox) Antri

Features & advantages

Gentle and low-pulsation conveying:

Precise dosing

Easy cleaning and sterilisation (CIP)

Fast maintenance

Seamless integration due to rotatability of the pump head

maximum flexibility thanks to various connection types (milk pipe, camlock, flange and tri-clamp)

fulfils the highest safety standards with FDA conformity and ATEX certification.

Wobble plate pump - TRP030 series

Suitable for small to medium applications

The mid-range solution for medium to large applications

The TRP030 wobble plate pumps series is the ideal choice for companies that require a reliable and powerful pump solution for medium to large applications. With an impressive flow rate of up to 12,000 l/h and a discharge pressure of up to 15 bar, this model offers the perfect combination of efficiency, versatility and reliability. Whether in the paint and coatings industry, the sealants and adhesives industry, the pharmaceutical industry, the cosmetics industry, the oil industry or the food industry - the TRP030 masters demanding processes with ease.

Motor power: up to 5.5 kW

Diameter: 170 mm Length: 340 mm (plus motor and gearbox)

Weight: 90 kg (incl. motor and gearbox) Antri

Features & advantages

Gentle and low-pulsation conveying:

Precise dosing

Easy cleaning and sterilisation (CIP)

Fast maintenance

Seamless integration due to rotatability of the pump head

maximum flexibility thanks to various connection types (milk pipe, camlock, flange and tri-clamp)

fulfils the highest safety standards with FDA conformity and ATEX certification.

Wobble plate pump - TRP080 series

Suitable for small to medium applications

The Goliath of wobble plate pumps

The TRP080 wobble plate pumps series is the Goliath of swash ring pumps and the ideal choice for large industrial applications. With an impressive flow rate of up to 30,000 l/h and a discharge pressure of up to 15 bar, this pump offers the perfect combination of performance, efficiency and reliability. The TRP080 is specially designed for demanding processes in various industries and fulfils the highest standards in pumping technology.

Motor power: up to 7.5 kW

Diameter: 210 mm Length: 440 mm (plus motor and gearbox)

Weight: 135 kg (incl. motor and gearbox) Antri

Features & Benefits

Gentle and low-pulsation conveying:

Precise dosing

Easy cleaning and sterilisation (CIP)

Fast maintenance

Seamless integration thanks to the rotatability of the pump head

maximum flexibility thanks to various connection types (milk pipe, camlock, flange and tri-clamp)

fulfils the highest safety standards with FDA conformity and ATEX certification.

Single and multi-layer containers

Innovative water purification: Our single and multi-layer filters for optimum quality

Filtration is an essential part of water treatment. The standardised requirements of DIN 19605 and DIN 19643 for the treatment of swimming and bathing pool water enable safe and effective filtration operation.

In order to maintain the required water quality and water parameters, e.g. in accordance with DIN 19643, a high level of dirt retention and good flushability of the filters are necessary. The hydraulic conditions in the filter tank are optimised to achieve uniform flows to reduce particles and the rinsing conditions are optimised to ensure very clear water at the filter outlet.

These conditions also make it possible to use activated carbons to reduce chlorine by-products without any problems and without this light filter material being washed out during rinsing. The design and high quality workmanship of our filter tanks ensure excellent water quality for many years.

Water filtration - why it's so important

In order to ensure that the water is always of a good, consistent quality in terms of hygiene, safety and aesthetics, the size and equipment of the filter system must be based on the water load and the amount of impurities. The filter has the task of removing turbidity from the water with the help of an appropriate filter medium.

The appropriate dirt feed (e.g. the pool hydraulics of a swimming and bathing pool) and good rinsability of the filter while maintaining the operating conditions are of the utmost importance for successful treatment. Safe and effective filtration operation is made possible by complying with the standardised requirements specified in DIN 19605.

MEMDOS SMART LPX

MEMDOS SMART LPX – reliable chemical dosing

With the new stepper motor technology of the MEMDOS SMART LPX, even the smallest quantities can be dosed with high precision.For demanding and complex dosing tasks, the new generation offers a variety of attractive solutions. The LPX series is available in eight performance ranges and is suitable for network operation (ModbusRTU). In addition, the new generation of smart pumps has a full-colour 3.5-inch touchscreen display for easy and safe operation.And for even more flexibility, the smart pumps can be ordered ex works with a left- or right-handed display.

1000:1 rejection rate for MEMDOS SMART LPXGraphic display with multilingual menu

Display of the delivery rate in 7 different units

Pump base for standard or wall mounting

Password protection and adjustable areas

Alarm status shown in colour on the display

Calibration mode

Slow mode: 25%, 50%, 75%

Diaphragm replacement programme

Bleed function

Message storage

Software backup of four memory locations

Detachable display (optional)

Display position rotated (optional)

Available on request: Option to operate multiple pumps via a single display

Manual control, 0 – 100%

pulse control, constant or dynamic

analogue control 0/4 – 20 mA, scalable

batch dosing: manual start, external start, interval or timer function

network operation, Modbus RTU

Release input (external start/stop)

Level input with pre- and main alarm

Pulse input, step-up and step-down

Analogue input 0/4 – 20 mA

Diaphragm rupture detection (optional)

pulse output: stroke feedback, alarm or pulse forwarding

analogue output 0/4 – 20 mA, scalable

alarm relay output (1 and 2), adjustable