„Our modern dosing systems contribute to making fluids management in the global chemical industry safer and more efficient." - Heinz Lutz, CEO of Lutz-Jesco GmbH

Because safety is paramount!

Employing materials that are especially suited for use with aggressive media, Lutz-Jesco dosing systems and pumps guarantee safe processes in the chemical industry. Modern safety functions such as automatic diaphragm rupture detection and an intuitive operating concept increase operating safety for handling aggressive, toxic and flammable substances. We always put safety first!

The highest precision!

Since precision is the top priority in the chemical industry, Lutz-Jesco has developed state-of-the-art drive technology and intelligent micro-processor controls for dosing systems and pumps. These enable the homogeneous and low-pulsation delivery of even the smallest quantities of liquid, and the precise control of the dosing quantities – even under fluctuating process conditions such as varying back pressure.

Staying flexible for the future

Lutz-Jesco dosing systems and pumps provides users in the chemical industry with maximum flexibility. An extensive product range covers a wide variety of pressure ranges, dosing quantities and viscosities. The systems are used as stand-alone devices, but can also be connected seamlessly to control systems via suitable interfaces for the industry 4.0 era. Contact our experts to find the ideal solution that meets your needs.

Applications for the chemical industry

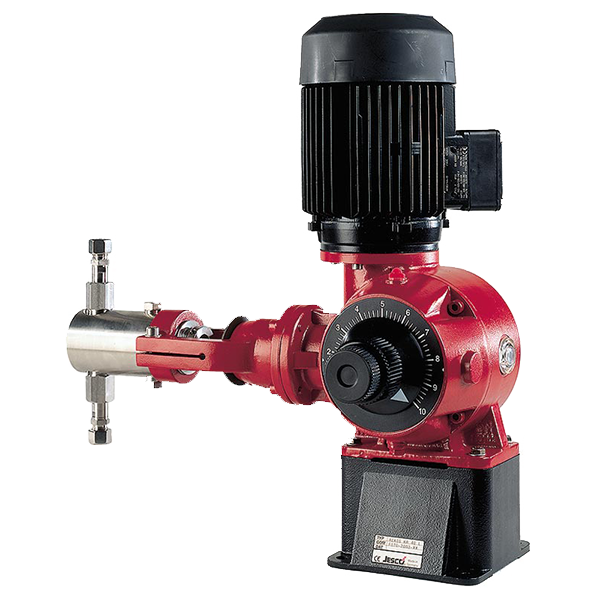

Products for the chemical industry

info@jescome.com